PTFE SEALS

Product Introduction

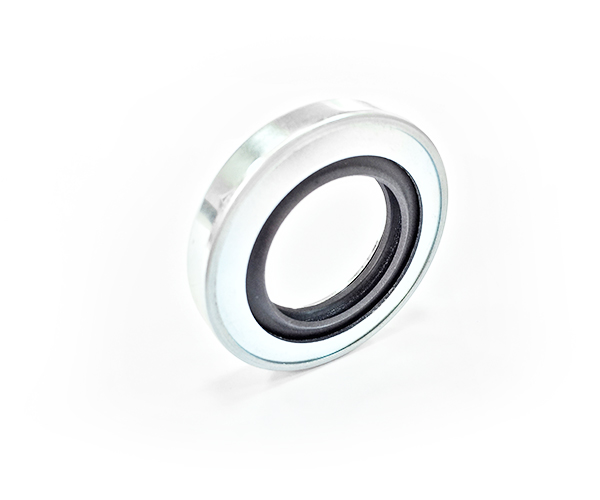

Polytetrafluoroethylene, also known as PTFE, is a synthetic material that provides excellent qualities than any other traditional lip materials cannot offer. It has the ability to withstand aggressive working environment such as resisting high temperatures, high pressures, and chemical interference. PTFE seals are also applicable in dry running environment with high surface speed and low friction rate.

PTFE seals advantages:

- High chemical resistance

- High pressure withstanding ability

- Applicable in high speed, dry running operation.

- Wide range temperature tolerance from -70°C to 250°C.

- Decrease the possibility of shaft damaging.

As PTFE seals have the sealing qualities that other elastomers cannot provide, it is used in wide range fields of application.

PTFE Seals application:

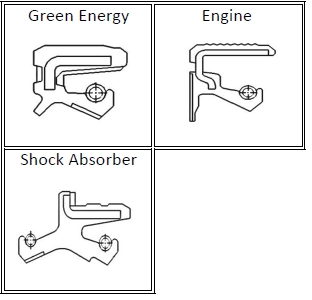

- Automotive application such as motors, A/C compressor, and so on.

- Hydraulic sealing such as wiper, rod seal, pump seal, piston.

- Food industry (Certain PTFE compounds are approved by the FDA.)

- Pharmaceutical industry.

- Environments that contains corrosive fluids, gases, or harsh chemical substances.

Since PTFE seals’ elastic properties are different from rubber, installation of PTFE seals need to be cautious in order to prevent damage of the sealing lip to ensure proper operation and function. PTFE seals are easily damaged when installed without proper care. In aids of installing PTFE seals, installation tools are often used to overcome difficulties, tools such as thin-walled installation tools made from plastic or metal.